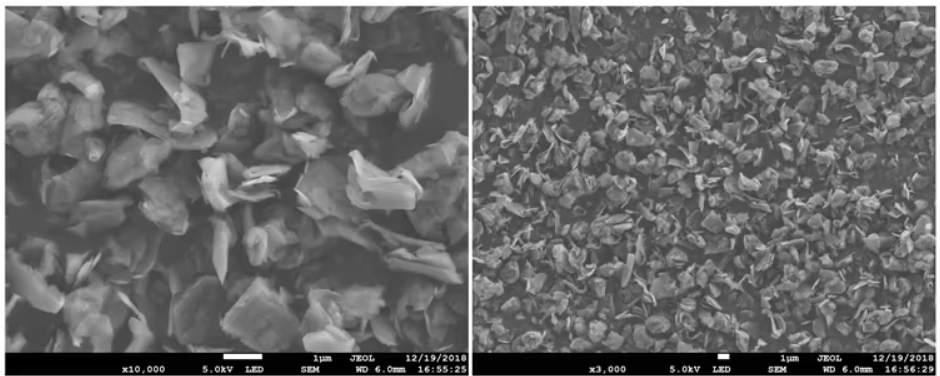

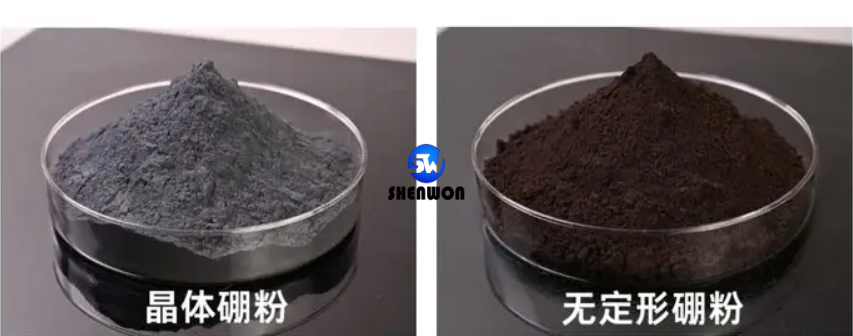

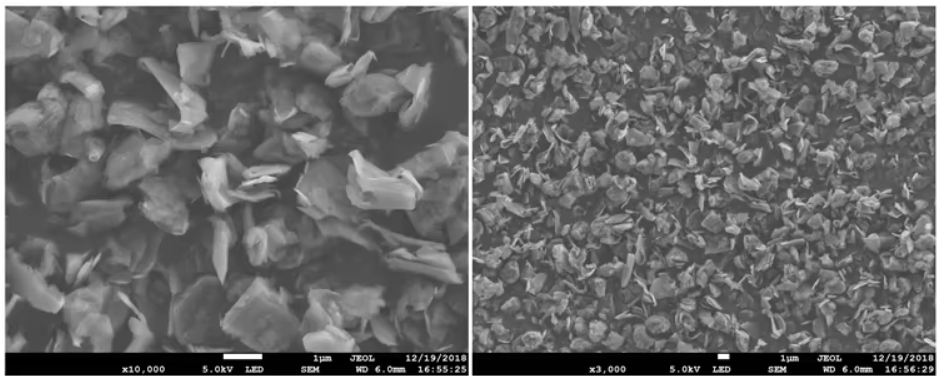

Titanium diboride (TiB2) is the most stable compound of boron and titanium, with a C32 structure that combines in the form of valence bonds and belongs to the hexagonal crystal system of quasi metallic compounds. The structural parameters of its complete crystal are: a is 0.3028nm, C is 0.3228nm. The boron atomic plane and titanium atomic plane alternate in the crystal structure to form a two-dimensional network structure, where B is covalently bonded with three other B atoms, and the excess electron forms a large π bond. The layered structure of boron atoms similar to graphite and the outer electrons of Ti determine the good conductivity and metallic luster of TiB2, while the Ti-B bond between the boron and titanium atomic planes determines the high hardness and brittleness of this material.

Characteristics of titanium diboride as structural and functional materials:

① In terms of structural materials. The high strength and hardness of titanium boride make it suitable for making cutting tools, wire drawing films, sandblasting nozzles, and hard tool materials. At the same time, it can also be used as an additive in composite materials.

② In terms of functional materials. The resistivity of titanium boride is very similar to that of pure iron, so it has great potential in functional materials. By utilizing the electrical properties of titanium boride, flexible PTC materials can be made.

1. Conductive ceramic materials. It is one of the main raw materials for vacuum coating conductive evaporation boats.

2. Ceramic cutting tools and molds. Can manufacture precision machining tools, wire drawing dies, extrusion dies, sandblasting nozzles, sealing components, etc.

3. Composite ceramic materials. As an important component of multi-component composite materials, it can be used to form composite materials with TiC, TiN, SiC and other materials to produce various high-temperature resistant components and functional components, such as high-temperature crucibles, engine components, etc. It is also one of the materials used to make armor protection materials.

4. Aluminum electrolytic cell cathode coating material. Due to the good wettability between TiB2 and molten aluminum metal, using TiB2 as the cathode coating material for aluminum electrolysis cells can reduce power consumption and prolong cell life.

5. Made into PTC heating ceramic materials and flexible PTC materials, it has the characteristics of safety, power saving, reliability, and easy processing and molding. It is a high-tech product that updates and replaces various types of electric heating materials.

6. It is a good strengthening agent for metal materials such as Al, Fe, Cu, etc.

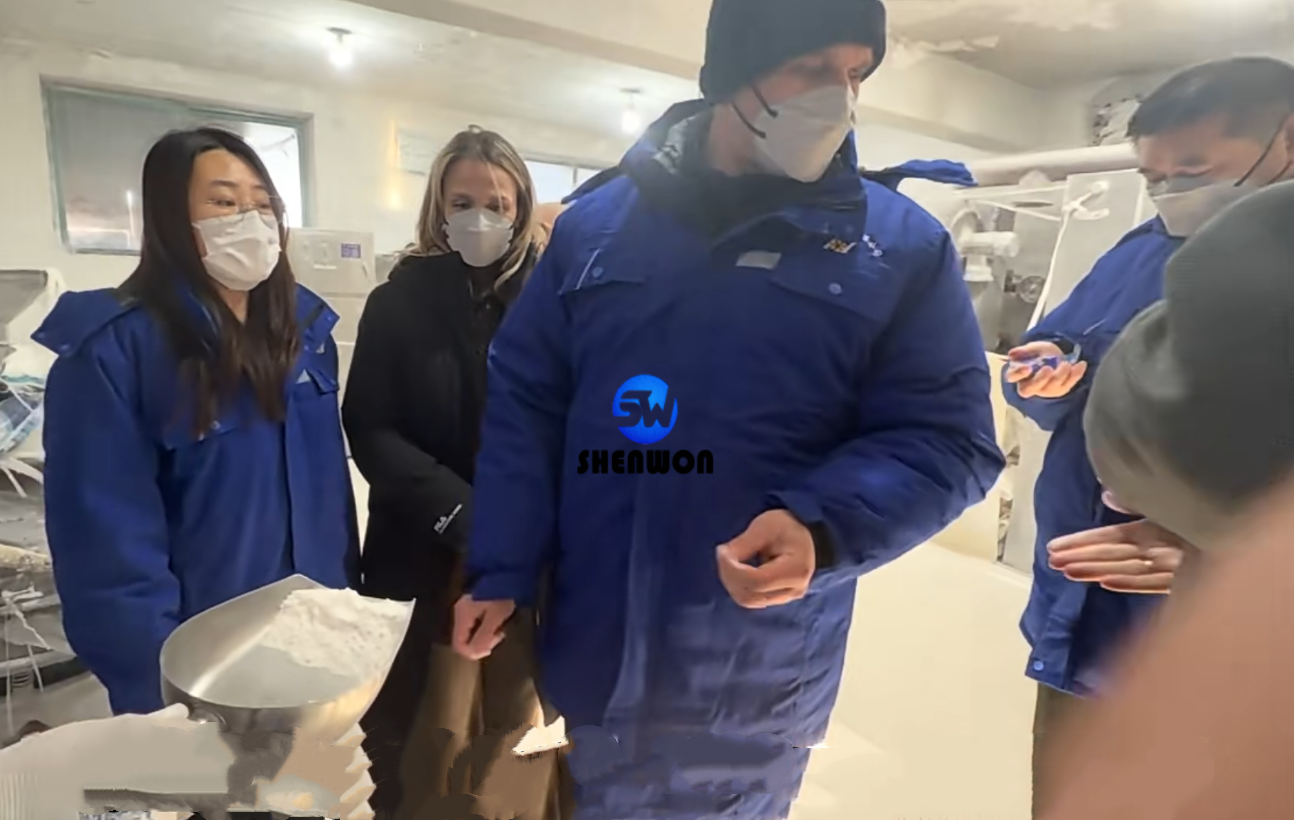

The company has set up 2 professional laboratories to continuously and customize products per clients’ requirements. Doctors: 2 people,Senior engineers:12 people.

The company is constantly building new factories, it has 5 production lines,more than 150 workers.

The products produces in each batch undergo , raw materials inspected before producing, working in process and finished goods is inspected before shipping.

You can contact us by filling in the information below, the official service consultant will contact you within 12 hours, please keep the phone open. If you have any questions or suggestions, please fill in the following form, Dachegn will serve you wholeheartedly.